In the fiercely competitive e-liquid market, consumer expectations are sharply defined by flavor. A vape product that tastes off, flat, or oxidized upon opening will almost certainly lead to product returns, brand devaluation, and negative reviews. Yet among the many formulation and design priorities, one factor remains severely underestimated: storage conditions.

How your e-liquid is stored—from raw material warehousing to final retail shipment—can fundamentally shape the final flavor experience. Whether it’s light, heat, oxygen exposure, or packaging material, every variable can degrade volatile aroma compounds that define your signature flavors.

Aroma degradation

This article explores in detail how environmental factors influence vape flavor integrity, and what strategies manufacturers can adopt to minimize aroma loss and ensure consistency across every batch.

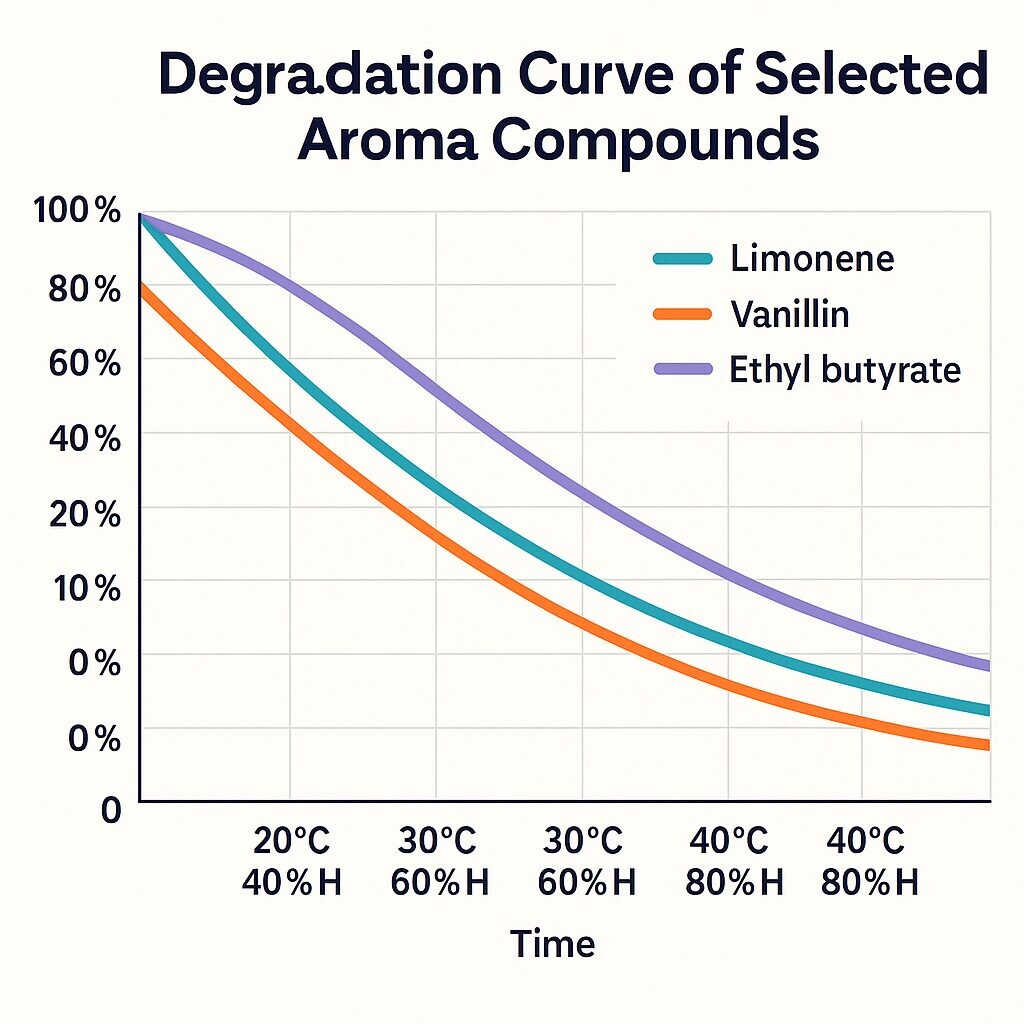

The aromatic experience of e-liquids is crafted using volatile compounds—aldehydes, esters, ketones, terpenes, and more. These molecules are chemically sensitive and prone to degradation.

Flavor Stability Fact: Limonene begins oxidizing into carvone and limonene oxide at just 30–35°C, drastically altering citrus profiles and producing bitterness.

Aromatics are measured in parts per million (ppm), meaning even slight degradation has noticeable sensory impact. This makes flavoring arguably the most storage-sensitive component of the e-liquid system.

To maintain flavor integrity, it’s critical to understand the main environmental stressors:

Study Insight: In a controlled trial, fruity e-liquid formulas lost up to 40% aroma intensity after being stored at 45°C for 30 days.

Degradation curve of selected aroma compounds

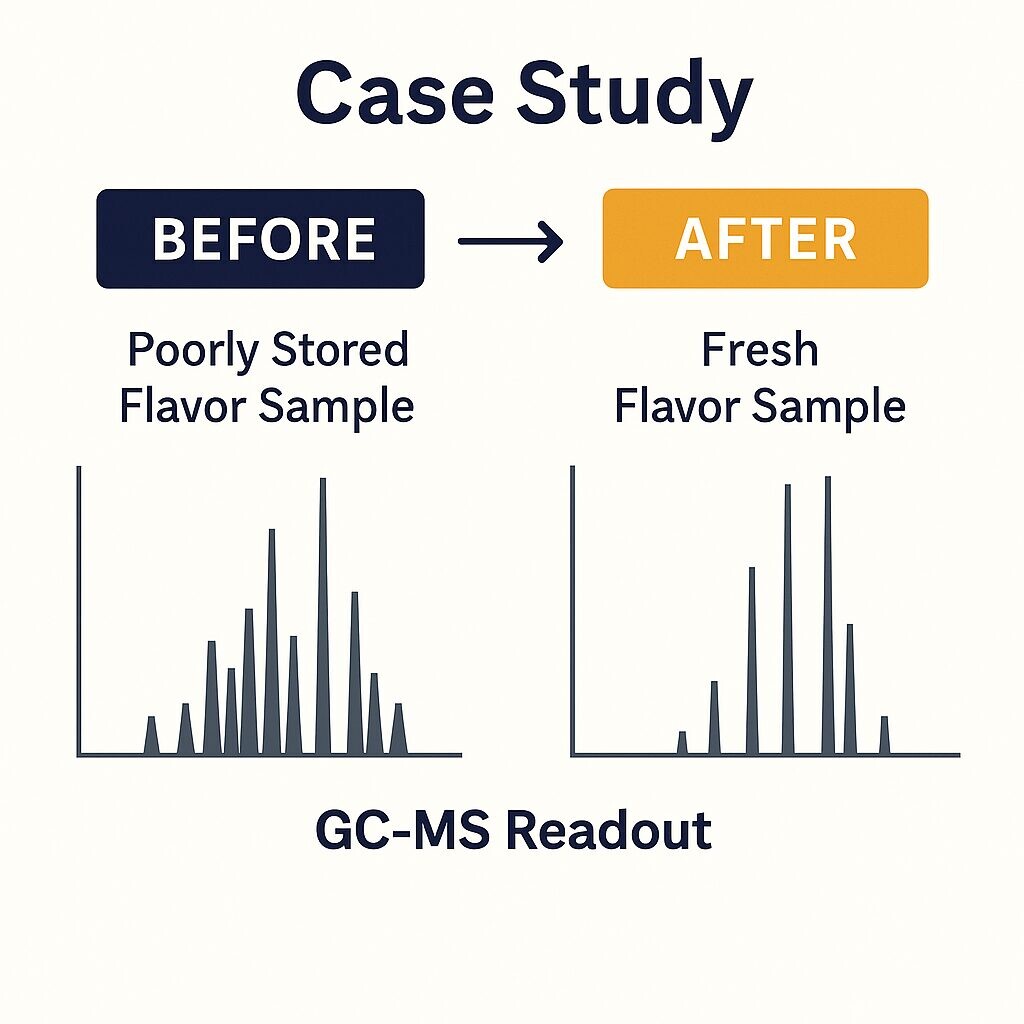

Packaging is not just branding—it’s a functional barrier that determines whether your e-liquid flavor stays intact.

Many brands have reported large-scale flavor failures due to improper storage, including:

GC-MS readout of a poorly stored flavor vs. fresh

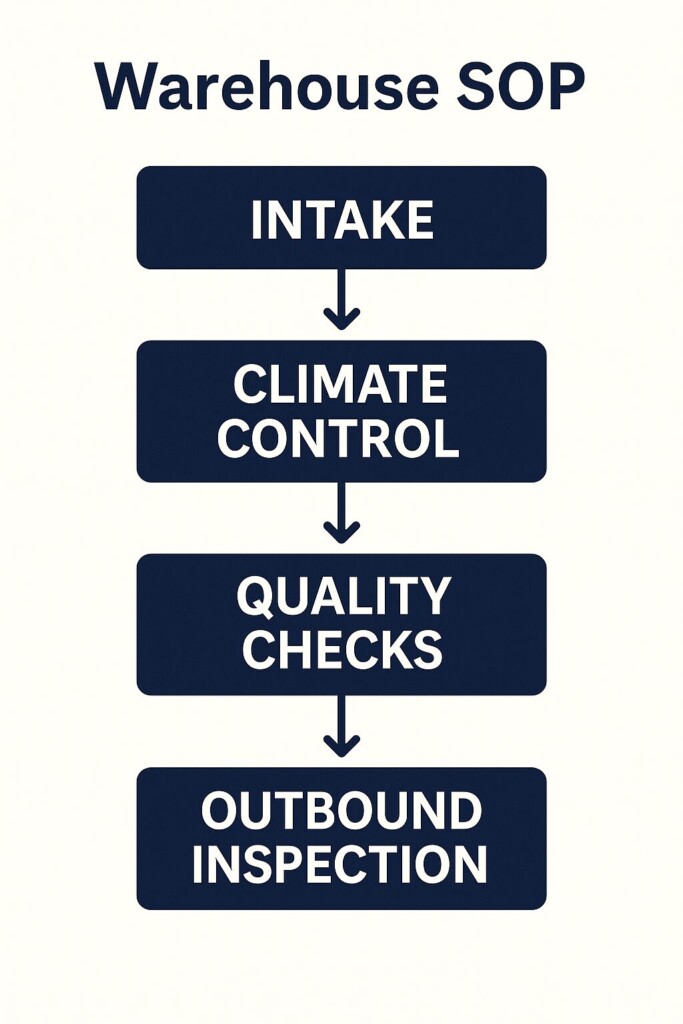

Maintaining flavor stability isn’t just formulation—it’s QC.

Work with suppliers who understand storage-sensitive formulation. For instance, CUIGUAI Flavoring offers pre-tested e-liquid flavors designed for high-temperature logistics, long storage periods, and global transit, using advanced stability testing and encapsulated carriers.

Flowchart warehouse SOP

E-liquid flavor doesn’t just depend on formulation—it depends on preservation. Even the most premium flavorings can degrade if left at the mercy of high heat, sunlight, or air. Aroma loss is invisible, yet its commercial impact is very real.

To safeguard your brand, invest in understanding storage dynamics, refine your packaging strategies, and collaborate with suppliers who test flavor stability under real-world stress. Your consumers aren’t just vaping nicotine—they’re tasting your brand. Make sure they’re tasting it at its best.

Looking to build resilient, storage-optimized vape flavors? Contact CUIGUAI Flavoring for a consultation on our lab-tested, transit-proof aroma solutions.

Keywords: flavor storage stability, aroma loss, warehouse impact flavor, vape flavor degradation

Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jun 6, 2025

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy