Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jan 08, 2026

Cinnamaldehyde Molecule & Cinnamon Bark

In the dynamic world of e-liquid formulation, few profiles are as polarizing—or as technically demanding—as cinnamon. When executed correctly, a cinnamon flavor offers a warm, robust, and sweetly spicy sensory experience that is a staple in dessert, bakery, and spiced beverage profiles. It provides the “throat hit” that many former smokers crave, alongside a complex aromatic profile that synthetic substitutes rarely replicate.

However, the pursuit of authentic cinnamon flavor almost invariably leads formulators to one primary compound: cinnamaldehyde.

While essential for flavor authenticity, cinnamaldehyde presents significant material science and biological challenges that can derail a product launch if not expertly managed. For years, the vaping industry has grappled with the “tank cracker” phenomenon, where certain flavors cause catastrophic failure in plastic hardware. Simultaneously, formulators must navigate the biological reality that cinnamaldehyde is a known dermal sensitizer.

As a manufacturer of specialized flavorings, we believe that mastering these challenges requires a deep understanding of the underlying chemistry. Authentic spice profiles do not have to be abandoned; they must be engineered. This article serves as a technical deep dive into the mechanisms of cinnamaldehyde reactivity, offering actionable strategies for mitigating hardware damage and addressing consumer sensitivity concerns.

To control cinnamaldehyde, one must first understand its structure. trans-Cinnamaldehyde (C6H5CH=CHCHO) is an organic compound that gives cinnamon its flavor and odor. It is a pale yellow, viscous liquid that occurs naturally in the bark of cinnamon trees and other species of the genus Cinnamomum.

Chemically, it is an α,β-unsaturated aldehyde. This structure is key to both its prized sensory characteristics and its problematic reactivity. The aldehyde group (-CHO) is highly reactive, capable of oxidizing into cinnamic acid upon exposure to air, which can alter the flavor profile over time and potentially increase acidity. Furthermore, the conjugated double bond system within the molecule makes it susceptible to various addition reactions.

In the context of e-liquid—typically a mixture of Propylene Glycol (PG), Vegetable Glycerin (VG), and nicotine—cinnamaldehyde is relatively stable in solution. The challenges arise not when it is sitting in the bottle, but when it interacts with the materials of the vaping device or the biology of the end-user. It is a potent organic solvent in its own right, and its relatively high vapor pressure contributes to its intense aromatic delivery. Understanding cinnamaldehyde not merely as a “flavor” but as a reactive chemical species is the first step toward responsible formulation.

The most infamous characteristic of cinnamon e-liquids is their propensity to crack plastic tanks. In the early days of vaping, this was a frequent consumer complaint, leading to damaged hardware and leaked liquid. While hardware has evolved, the underlying chemistry remains a critical consideration, especially as pod systems and disposable devices often revert to cost-effective polymer materials.

It is a common misconception that cinnamaldehyde is “acidic” and therefore “eats” the plastic. The actual mechanism is far more interesting from a materials science perspective: it is a process known as environmental stress cracking (ESC) or solvent-induced crazing.

Polycarbonate vs. Ultem Vape Tank Comparison

Many clear plastic tanks, particularly older generations or budget-friendly modern disposables, are manufactured from amorphous polymers like Polycarbonate (PC) or Polymethyl Methacrylate (PMMA, or acrylic). These materials are composed of long polymer chains that are randomly entangled, much like a bowl of cooked spaghetti. These entanglements give the plastic its strength and rigidity under normal conditions.

Cinnamaldehyde acts as a plasticizing solvent for these specific polymers. Because of its chemical structure and polarity, cinnamaldehyde molecules can diffuse into the polymer matrix of PC and PMMA. When they penetrate between the polymer chains, they reduce the intermolecular forces (van der Waals forces) holding the chains together.

This absorption causes the polymer to swell. If the plastic is under stress—which is almost always the case in a vape tank due to manufacturing processes, threading pressure, or the thermal cycling of the coil heating up and cooling down—the swelling is not uniform. The weakened intermolecular forces allow the chains to slide past one another more easily. This leads to the formation of “crazes,” which are tiny voids bridged by highly drawn polymer fibrils. As these crazes grow and coalesce, they develop into macroscopic cracks, eventually leading to catastrophic failure of the tank.

This phenomenon is well-documented in material engineering, where aldehydes and ketones are known aggressive agents against polycarbonate. According to material science resources, the solubility parameter of the solvent (cinnamaldehyde) closely matches that of the polymer, facilitating this destructive absorption.

Citation 1: A study published in the Journal of Applied Polymer Science highlights the mechanisms of solvent-induced crystallization and cracking in polycarbonates, detailing how organic solvents penetrate the amorphous regions and induce mechanical failure under strain (e.g., “Solvent-induced crystallization of polycarbonate,” J. Appl. Polym. Sci.).

The solution to this hardware issue lies in material selection. Crystalline polymers or materials with higher chemical resistance are impervious to cinnamaldehyde’s solvent effects at the concentrations used in e-liquids.

For the e-liquid manufacturer, understanding this is vital for consumer education. If you produce a high-cinnamaldehyde SKU, appropriate warnings regarding hardware compatibility are a mark of professional responsibility.

While hardware can be replaced, human biology is less forgiving. The second major challenge with cinnamaldehyde is its status as a potent sensitizer. This is distinct from simple irritation.

Irritation is an immediate, localized reaction. If you apply pure cinnamaldehyde to your skin, it will cause redness and a burning sensation almost instantly. This is a direct toxic effect on skin cells.

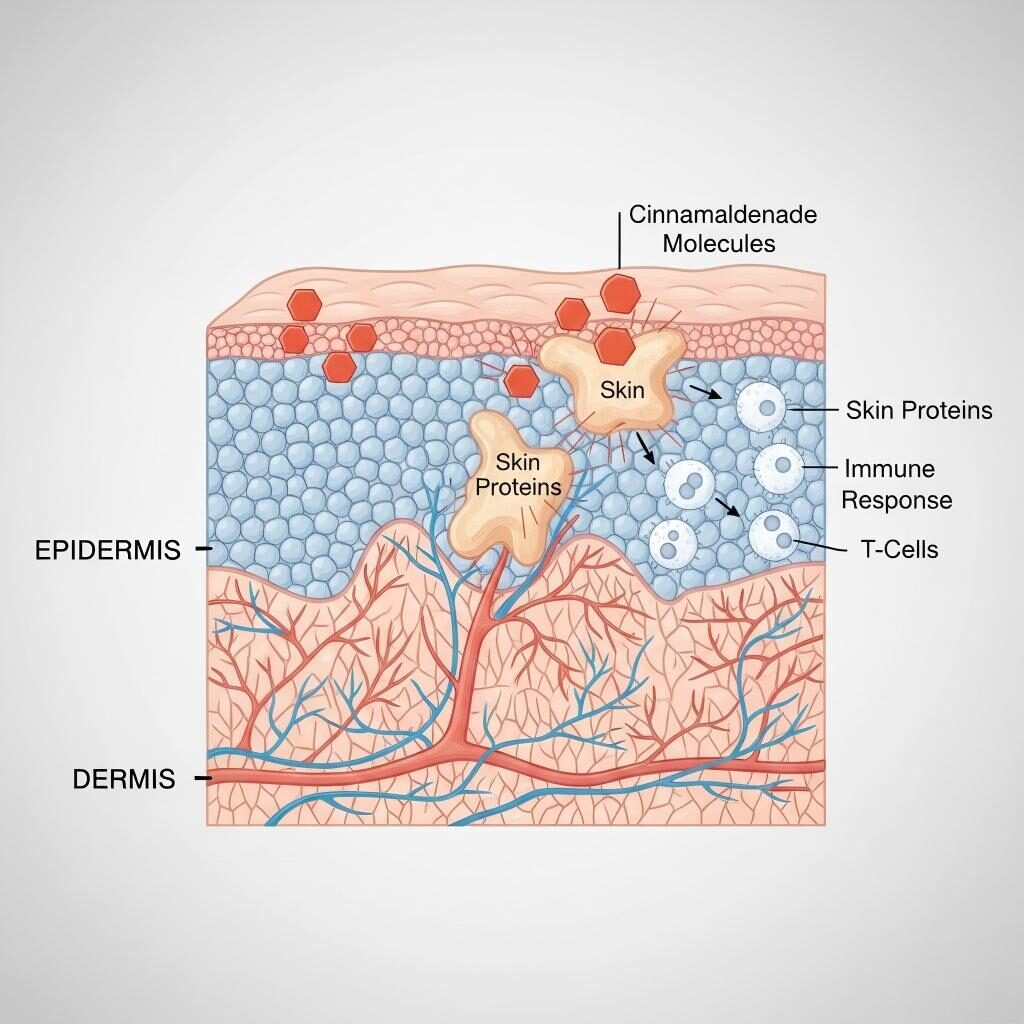

Sensitization (allergic contact dermatitis) is an immunologic response. Cinnamaldehyde is a “hapten.” Haptens are small molecules that are not allergenic by themselves but can penetrate the skin and bind to body proteins. This new hapten-protein complex is then recognized by the immune system as foreign.

Upon initial exposure, the body may develop memory T-cells specific to this complex. This process is called induction and usually has no visible symptoms. However, upon subsequent exposure, even at much lower concentrations, these memory T-cells trigger an aggressive inflammatory response, leading to redness, swelling, vesicles, and intense itching.

The potential for cinnamaldehyde to cause sensitization is widely recognized in toxicological literature and regulatory frameworks governing cosmetics and fragrances. While e-liquid regulations vary globally, the toxicological benchmarks established by organizations like the Research Institute for Fragrance Materials (RIFM) and the International Fragrance Association (IFRA) are critical reference points for responsible formulation.

IFRA standards, for example, place strict limits on cinnamaldehyde concentration in products intended for skin contact (like perfumes or lotions) to prevent induction of sensitization. While vaping is primarily an inhalation exposure pathway, dermal contact occurs during refilling, leaks, or handling of the device. Furthermore, the mucous membranes of the respiratory tract can also participate in sensitization pathways.

Dermatological studies consistently identify cinnamaldehyde as one of the most common allergens found in fragranced products, often included in standard patch test series used by dermatologists to diagnose contact allergies.

Citation 2: The National Center for Biotechnology Information (NCBI) via PubMed hosts numerous studies confirming cinnamaldehyde as a frequent cause of allergic contact dermatitis, emphasizing its mechanism of protein binding in the epidermis (e.g., studies on “Cinnamaldehyde-induced allergic contact dermatitis”).

For the e-liquid formulator, this means that simply achieving a great flavor is not enough. We must consider the “toxicological burden” we are placing on the consumer. A flavor that is perfectly safe for 90% of the population may cause significant discomfort for the 10% who are already sensitized or may induce sensitization in new users if concentrations are excessively high.

Given the material and biological constraints, how do we deliver the authentic cinnamon flavor that the market demands safely? Abandoning the profile is unnecessary. Instead, we must employ sophisticated formulation strategies.

The “dose makes the poison” is the fundamental tenet of toxicology. The most direct mitigation strategy is limiting cinnamaldehyde concentration to the functional minimum.

Many inexperienced mixers use excessive amounts of flavoring to achieve “punch.” A professional approach involves finding the sensory threshold where authentic flavor is achieved without unnecessary excess. We have found that authentic cinnamon profiles can often be achieved at significantly lower percentages when balanced correctly with supporting flavor notes (like creams, vanillas, or tobaccos) that round out the harshness without requiring more cinnamaldehyde.

Cinnamaldehyde Skin Immune Response

Flavor chemistry offers alternatives. While cinnamaldehyde is the primary constituent of cinnamon oil, other related molecules can provide similar spicy notes with different reactivity profiles.

By creating a “cinnamon accord” using a blend of these analogues alongside a reduced amount of cinnamaldehyde, a formulator can achieve complexity and reduce the overall reactive load of the e-liquid.

Citation 3: The Good Scents Company database and Fenaroli’s Handbook of Flavor Ingredients provide extensive data on flavor aroma chemicals, detailing the sensory profiles and chemical structures of substitutes like cinnamyl acetate, highlighting their differing reactivity compared to cinnamaldehyde.

The frontier of flavor science lies in encapsulation. This involves trapping the active flavor molecule within a protective matrix (often a carbohydrate or modified starch).

In the context of e-liquids, spray-dried or molecularly encapsulated cinnamaldehyde could theoretically limit its interaction with tank materials and skin until the moment of vaporization. The heat of the coil would break down the encapsulating matrix, releasing the flavor right when it is needed. While this technology is more common in food applications, its adaptation for e-liquids is a promising area of R&D that could resolve shelf-life stability and tank cracking issues simultaneously.

While less common in standard e-liquids, the stability of aldehydes can sometimes be influenced by the overall pH of the solution and the presence of antioxidants. Preventing the oxidation of cinnamaldehyde into cinnamic acid is crucial for flavor stability. The use of appropriate food-grade antioxidants (like tocopherols) in the flavor concentrate itself can improve the shelf life and ensure the end product remains true to profile.

As manufacturers of specialized flavorings, our role extends beyond simply supplying a scent in a bottle. We view ourselves as partners in our clients’ compliance and success.

The challenges of cinnamaldehyde exemplify why relying on generic, uncharacterized flavor sources is risky for commercial e-liquid brands. A reputable flavor house must perform the necessary legwork before the product reaches the formulator.

This includes:

The vaping industry is maturing. The “wild west” days of throwing any food flavoring into PG/VG are yielding to an era of scientific stewardship. As data on inhalation toxicology becomes clearer, brands that prioritize stable, well-characterized ingredients will lead the market.

Citation 4: Recent industry reports from analysts like Grand View Research regarding the e-cigarette and vape market emphasize a growing trend toward product quality, transparency in ingredients, and regulatory compliance as key drivers for future market growth and consumer trust.

Cinnamaldehyde is a demanding molecule, presenting genuine challenges to material integrity and human biology. Yet, its sensory profile remains unmatched. The solution is not to avoid it, but to respect its chemistry.

By understanding the mechanisms of polymer solvation and dermal sensitization, formulators can move from guesswork to engineering. Through precision dosing, the intelligent use of chemical analogues, and appropriate consumer education regarding hardware, we can continue to offer the rich, warming spice profiles consumers love, responsibly and sustainably. Flavor is art, but formulation is science.

E-Liquid GC-MS Laboratory Testing

Are you struggling with cinnamon formulations that crack tanks or mute over time? Do you need flavor concentrates engineered for stability and compliance?

Our technical team specializes in navigating complex flavor challenges. Contact us today to discuss your specific needs, request technical data sheets, or sample our scientifically formulated cinnamon accords designed for the modern vape market.

Request a Technical Consultation or Free Sample Kit:

| Contact Channel | Details |

| 🌐 Website: | www.cuiguai.com |

| 📧 Email: | info@cuiguai.com |

| ☎ Phone: | +86 0769 8838 0789 |

| 📱 WhatsApp: | +86 189 2926 7983 |

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy