Keywords: flavor drift vape, aroma fade vape, long-term flavor stability, vape flavor degradation, shelf life e-liquid flavor, CUIGUAI Flavoring

Flavor defines the essence of the vaping experience. Whether fruity, creamy, botanical, or tobacco-based, a well-balanced aroma profile is the emotional and sensory core of a user’s satisfaction. But even the most meticulously developed vape liquids are susceptible to time. Over weeks or months, they may undergo flavor drift — the gradual deviation of taste and aroma from their intended profile. This phenomenon is subtle but significant, capable of affecting brand reputation, customer satisfaction, and regulatory compliance.

In this post, we explore the underlying science, detection methods, and mitigation strategies behind aroma fade in stored e-liquids. Designed for R&D chemists, flavor formulators, vape OEMs, and QA professionals, this in-depth guide also includes visual data suggestions to enhance comprehension. We also highlight the best practices employed by CUIGUAI Flavoring, a leading flavor solution provider in the global vape industry.

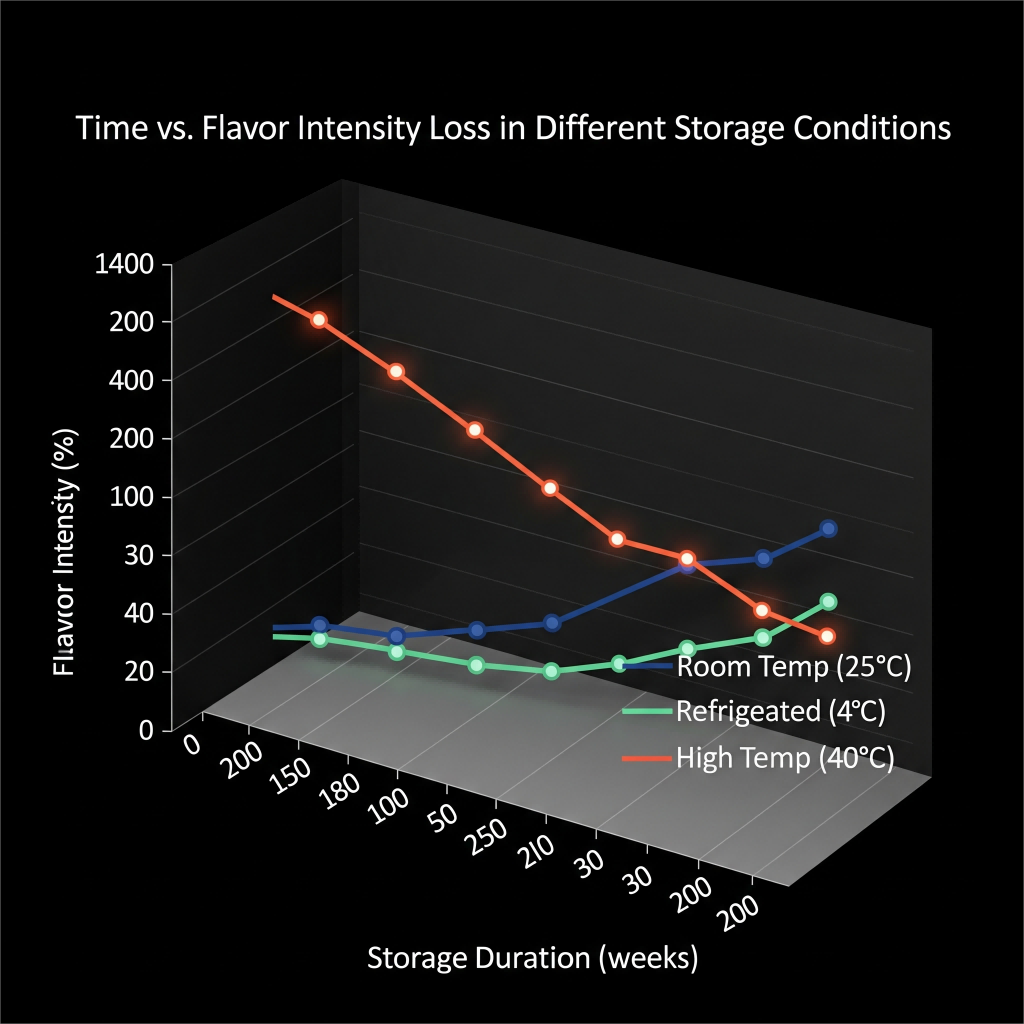

Time vs. Flavor Intensity Loss in Different Storage Conditions

Flavor drift in vape liquids is defined as a progressive change in aroma and taste over time due to chemical, physical, or environmental factors. It differs from product spoilage, which renders a product unsafe or unusable. Instead, flavor drift represents a form of sensory degradation: the product may remain technically “safe,” but its appeal and consumer satisfaction diminish.

Not all flavor changes are undesirable. Some e-liquid profiles, especially those with creamy, custard, or complex tobacco blends, benefit from maturation:

Maturation leads to greater smoothness, rounded edges, and deeper integration of notes.

Flavor drift, by contrast, manifests as:

Understanding this distinction is critical for quality control and brand consistency.

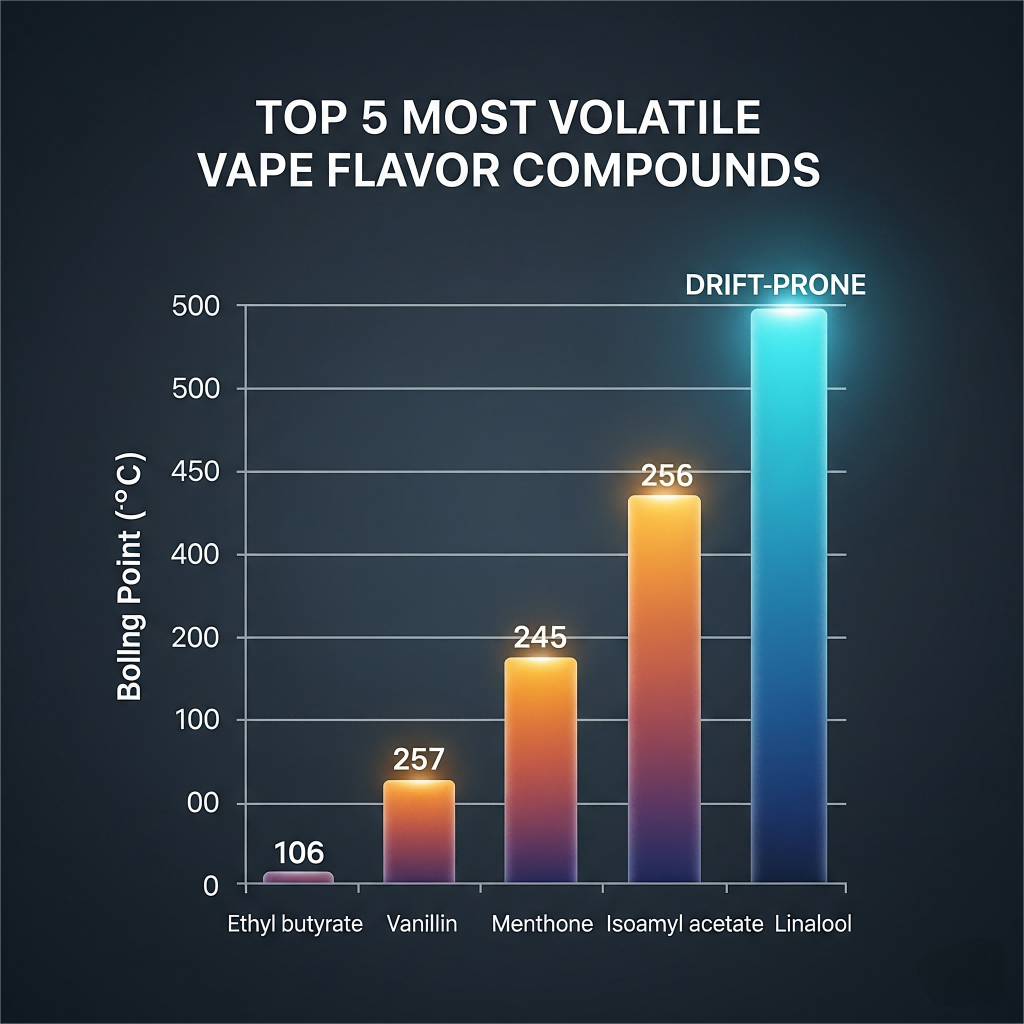

Many key flavor molecules in e-liquids are low-boiling-point compounds, including esters (fruity), aldehydes (citrusy), and ketones (buttery). These molecules:

Key Insight: Esters like ethyl butyrate can show a 40-60% reduction in vapor-phase intensity within 90 days at room temperature.

Propylene glycol and vegetable glycerin serve as carriers but also interact with flavor molecules:

Factors that accelerate degradation:

Even warehouse conditions during international shipping can affect flavor stability if not controlled.

Poor packaging choices amplify degradation:

Headspace volumedetermines oxidation rate post-opening

Top 5 Most Volatile Vape Flavor Compounds

Sensory analysis remains the gold standard for flavor consistency. A trained panel:

It is advisable to use 3-month, 6-month, and 12-month aged samples stored under various conditions for robust benchmarking.

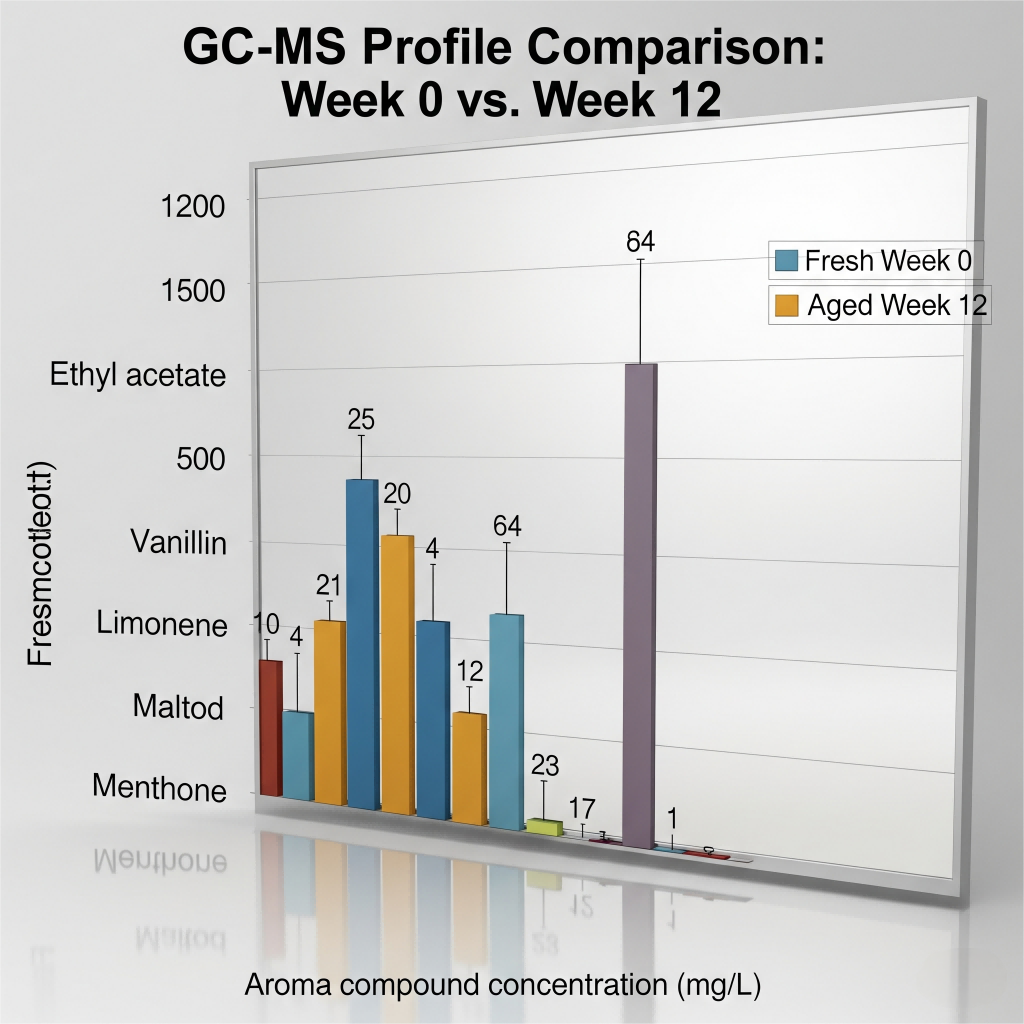

Gas Chromatography-Mass Spectrometry provides:

This is especially critical for high-value SKUs or regulated markets.

Color darkening often correlates with:

Spectrophotometry (e.g., at 420nm wavelength) offers a rapid proxy measure for oxidation-driven degradation.

GC-MS Profile Comparison: Week 0 vs. Week 12

Incorporating ingredients with stabilizing functions can reduce volatility:

Formulas with 1-3% fixatives often show 2x the aroma retention after 6 months.

Encapsulating aroma molecules in lipid or carbohydrate matrices:

CUIGUAI Flavoring utilizes proprietary encapsulation for thermally sensitive notes like litchi, blueberry, and vanilla custard.

| Factor | Optimal Range |

| Temperature | 15–22°C |

| Relative Humidity | 30–50% |

| Light | Dark storage only |

| Position | Upright, no shaking |

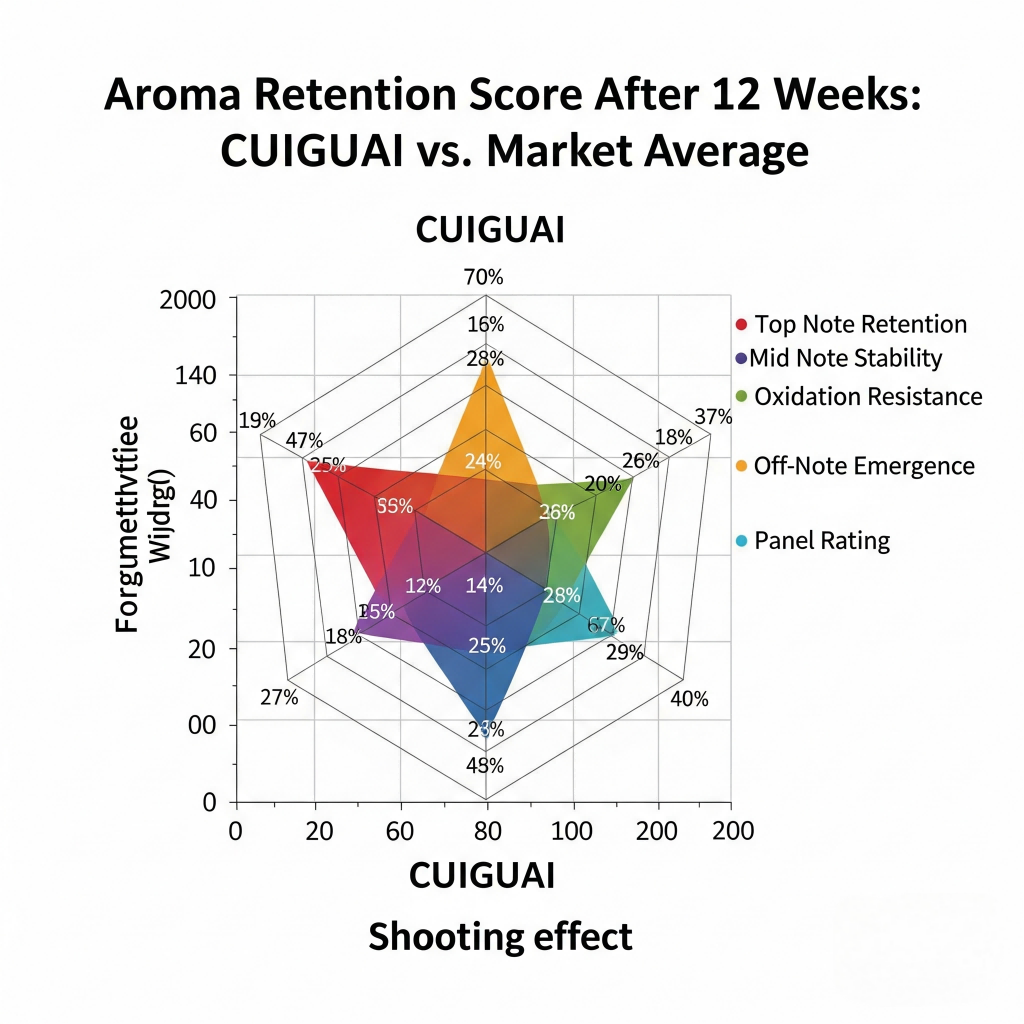

CUIGUAI Flavoring leads the vape industry in flavor longevity, thanks to its commitment to scientific formulation, stability testing, and customer-focused customization. Our practices include:

If flavor consistency is part of your brand promise, CUIGUAI Flavoring is your R&D partner of choice.

Contact us to request demo kits, custom shelf-life reports, or consult on a stability-optimized formulation.

Aroma Retention Score After 12 Weeks: CUIGUAI vs. Market Average

Flavor drift is not a mystery; it’s a consequence of chemistry, packaging, and process design. Addressing it requires:

With the support of partners like CUIGUAI Flavoring, vape brands can not only prevent flavor drift but engineer formulas that age gracefully and perform reliably over time.

The market increasingly favors brands that take flavor quality seriously. Don’t let your signature taste fade—design for the long haul.

About CUIGUAI Flavoring

CUIGUAI Flavoring is a premium manufacturer of vape-specific flavor concentrates based in China. Our R&D team specializes in high-impact, long-shelf-life flavor systems tailored to OEM and branded clients globally. Learn more at CUIGUAI official site.

Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jul 02, 2025

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy