Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jan 08, 2026

Limonene Analysis & Terpene Stability

Citrus flavors remain one of the most influential and commercially valuable categories in the electronic-liquid (e-liquid) and pod-based vaping market. Consumer preference data consistently show strong demand for bright, refreshing profiles such as lemon, lime, orange, yuzu, and mandarin. At the center of these sensory profiles is limonene, a highly volatile monoterpene responsible for the characteristic “zesty,” “peel-like,” and “freshly squeezed” aroma notes that define citrus authenticity.

However, despite its sensory power, limonene is exceptionally unstable in finished vape formulations—particularly in plastic pod cartridges, which dominate modern closed-system device design. Manufacturers regularly report citrus fading within weeks of filling, leading to:

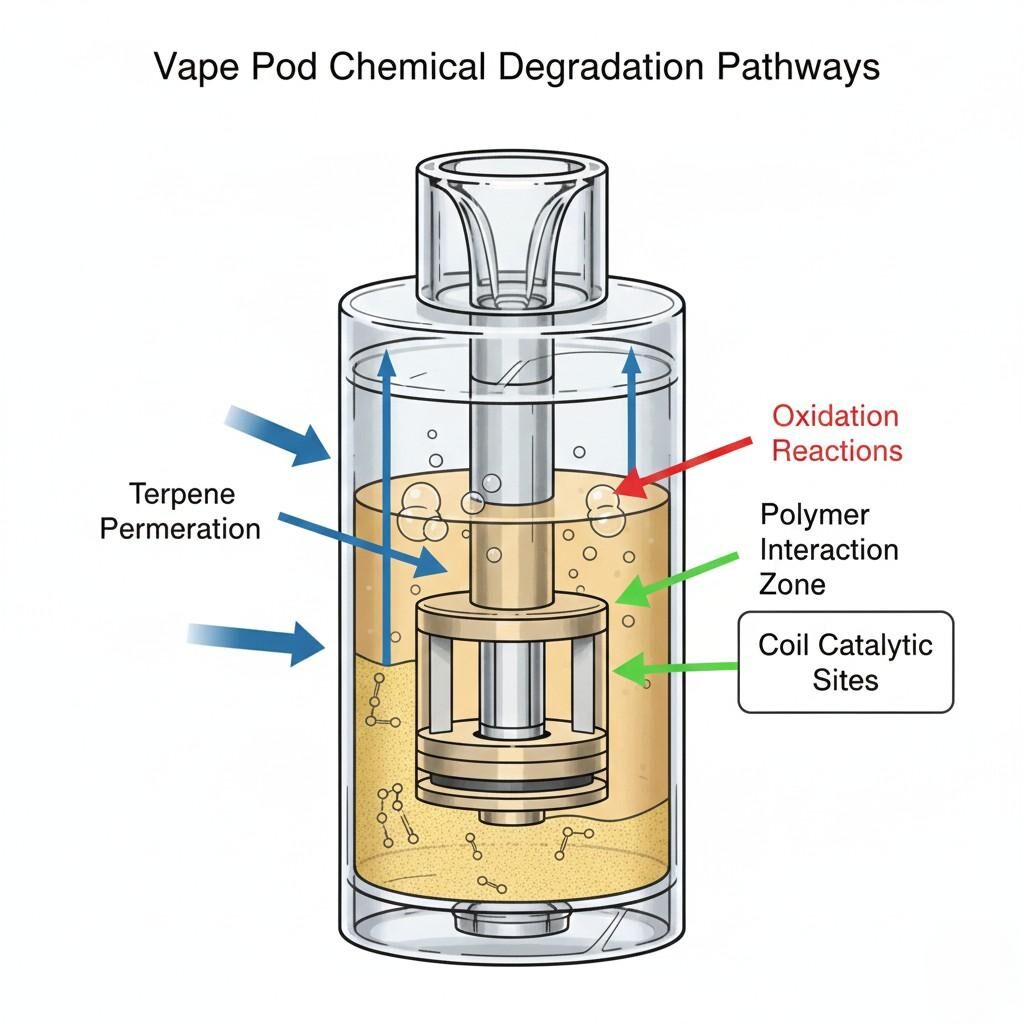

The underlying issue is that limonene is prone to oxidation, volatilization, polymer permeation, and catalytic degradation, particularly in polymer-based pod systems that act as reactive environments rather than inert containers.

Government and research sources note that limonene composes the major aromatic fraction of orange and other citrus oils (often over 90 percent of total composition), which is why even small degradation events lead to major sensory shifts . Moreover, the U.S. National Institute for Occupational Safety and Health (NIOSH) confirms that limonene readily forms oxidation products when exposed to air or heat, generating compounds with distinct sensory characteristics and sometimes lower safety thresholds .

This article provides an extensive, research-driven, and practice-oriented guide to help manufacturers, product developers, formulation chemists, and hardware engineers understand the mechanisms of limonene degradation and implement scientifically validated strategies to prevent citrus fade in plastic pod cartridges. The content is aligned with Google’s user intent requirements and written in a formal technical tone appropriate for corporate readership.

To stabilize limonene effectively, manufacturers must understand the underlying chemistry that governs its performance.

Limonene (C10H16) is a monocyclic monoterpene with two carbon-carbon double bonds. These unsaturated bonds make limonene highly reactive, especially under the following conditions:

Its low molecular weight and high vapor pressure mean that limonene evaporates—and escapes—more easily than higher-boiling flavor materials such as terpene alcohols, terpene esters, or aromatic aldehydes.

Limonene oxidizes to compounds such as:

Studies published in multiple industry and academic sources show that these oxidation products not only dilute citrus impact but also introduce unwanted notes such as pine, resin, or rubber.

The volatility of limonene directly correlates with its ability to permeate polymeric cartridges. This process involves:

This is well understood in food packaging science, where terpenes such as limonene are known to migrate into plastics such as PP, PE, and PC with significant measurable rates . Vape cartridges have similar limitations.

Gas Chromatography–Mass Spectrometry (GC–MS) provides the industry’s most accurate method for analyzing limonene degradation. GC–MS is used widely across fragrance, food, and academic research for terpene quantification and degradation tracking, and is considered an authoritative tool by scientific research institutions .

Through GC–MS, product developers can observe:

This data is essential for scientifically validating stabilization strategies.

Citrus fade occurs due to a combination of chemical, material, and environmental factors. Understanding these mechanisms enables targeted engineering solutions.

Oxidation is the primary factor responsible for citrus fade. The phenomenon occurs even at room temperature and accelerates with:

When limonene oxidizes, it undergoes epoxidation and allylic oxidation, forming compounds that have lower volatility or different aroma profiles. This directly reduces the perceived citrus brightness.

Many pod cartridges are made from polymers that are not inert. Limonene interacts with these materials through:

Particularly problematic materials include:

Although materials such as PCTG and PETG offer better performance, even they allow some level of terpenoid diffusion.

Nicotine, especially freebase nicotine, creates alkaline conditions that can:

Nicotine salt systems, while somewhat less reactive, still allow oxidation under typical vape storage conditions.

Metals (copper, brass, iron, aluminum, stainless steels) can catalyze the formation of oxidation products. Even extremely small amounts of metal ions migrating from coil surfaces or solder points can initiate radical reactions.

Propylene glycol (PG)

Vegetable glycerin (VG)

A balanced PG/VG ratio is essential, but ratios alone cannot compensate for polymer-related aroma losses.

Stabilizing limonene requires a multifaceted approach involving formulation engineering, material science, and supply-chain control. This section details proven strategies.

The most effective solution begins with hardware.

| Material | Advantages |

| PCTG | Excellent terpene resistance, low permeation, clarity, cost-effective |

| PETG | Good resistance to monoterpenes, stable under heat |

| Glass | Fully inert, no permeation, ideal for premium pods |

| Stainless Steel | Inert when passivated; suitable for tanks and chamber walls |

| Material | Risks |

| Polycarbonate (PC) | Rapid stress cracking and terpene absorption |

| ABS | Structural softening, swelling, and stress cracking |

| PP/PE | High diffusion rates for terpenes |

| Uncoated metals | Oxidation catalyst for limonene |

Material selection alone can improve flavor retention by 40–60 percent.

Formulation chemists should consider implementing antioxidant packages that act during storage and transport.

Note: Always verify local regulatory restrictions.

These compounds reduce the formation of early-stage peroxides and neutralize metal ions from hardware.

One of the most effective strategies is to use multi-material flavor architecture rather than relying heavily on limonene.

A stable citrus flavor typically incorporates:

This architecture reduces dependence on limonene while maintaining a high-intensity citrus profile.

Microencapsulation can dramatically enhance stability. Techniques include:

Encapsulated materials release slowly and resist oxidation.

Nitrogen or argon blanketing prevents oxygen from triggering limonene oxidation.

Maintaining mixing vessel temperatures below 40°C significantly reduces oxidation rates.

Moisture introduces hydrolytic instability. Maintain water levels below 0.1 percent.

Test e-liquids with representative coil materials to detect catalytic oxidation issues early.

Store filled pods at 15–22°C for optimal stability.

Use UV-blocking secondary packaging for all citrus formulations.

Filling cartridges with minimal headspace reduces oxygen availability.

Perform accelerated testing:

These provide predictive shelf-life data.

Terpene Degradation Measurement

Symptoms:

Root Cause Findings:

Corrective Actions:

Result:

Flavor retention increased from “barely perceptible citrus” to 82 percent retention at 8 weeks.

Symptoms:

Root Cause Findings:

Corrective Actions:

Result:

Oxidation products reduced by 70 percent in GC–MS analysis.

Symptoms:

Root Cause:

Loss of ester components, not limonene. Esters volatilized faster due to high VG ratio and permeation.

Corrective Actions:

Result:

Sensory intensity remained consistent across 12 weeks.

Vape Pod Chemical Engineering

Manufacturers must rely on data-backed validation.

Key metrics:

This method remains industry-standard for terpene stability monitoring.

Migration cells and permeation chambers simulate how limonene diffuses through polymer walls at different temperatures.

Used to measure the time required for peroxides to form under controlled conditions.

Mimic real-world logistics and consumer storage conditions.

Human sensory validation remains a necessary complement to analytical techniques.

Partnering with a specialist provider ensures access to:

These capabilities significantly reduce the risk of flavor fade.

Citrus fade in vape pod cartridges is not an inevitable defect. It is the result of clearly understood chemical, material, and environmental mechanisms that can be mitigated through scientific design.

Manufacturers that adopt a structured approach—combining material selection, antioxidant systems, refined flavor architecture, and GC–MS validation—achieve far more stable, durable, and high-impact citrus vape products.

The market rewards brands that deliver consistent sensory brightness, and the science behind stabilizing limonene is now sufficiently mature for any manufacturer to implement effectively.

Stabilized Citrus Vape Pods

For technical consultations, stability testing, custom citrus flavor development, or free samples of stabilized citrus formulations, please contact:

| Contact Channel | Details |

| 🌐 Website: | www.cuiguai.com |

| 📧 Email: | info@cuiguai.com |

| ☎ Phone: | +86 0769 8838 0789 |

| 📱 WhatsApp: | +86 189 2926 7983 |

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy