Explore the science behind flavor performance in different vapor devices — and how e-liquid formulation must adapt.

E-liquid flavors don’t always taste the same across devices—and for good reason. Many vapers report that their favorite juice tastes amazing in a mod, but dull or even unpleasant in a pod system. The difference isn’t just subjective; it’s deeply rooted in how e-liquid interacts with the hardware.

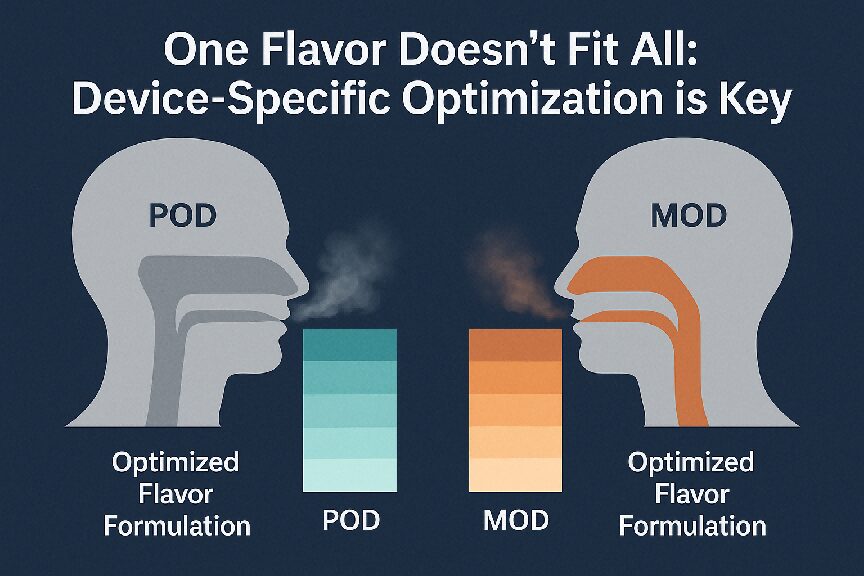

This article unpacks the science behind this phenomenon, giving manufacturers, formulators, and flavor chemists the tools to optimize for both pods and mods. Whether you’re developing flavors for closed pod systems or high-wattage box mods, understanding device-specific behavior is no longer optional—it’s essential.

| Parameter | Pod System | Mod Device |

| Coil Resistance | High (≥1.0 ohm) | Low (<0.5 ohm) |

| Wattage Output | Low (7–15W) | High (20–200W) |

| Airflow | Restricted | Adjustable / Open |

| Vapor Production | Low | High |

| Refillability | Often closed system | Usually open |

These factors influence the rate and profile of aerosol generation, directly affecting how flavor compounds are volatilized and perceived.

Flavor compounds have different boiling points. A compound like vanillin may vaporize at 170°C, while others, such as esters or terpenes, volatilize at much lower or higher temperatures. Mods, with their high power output, reach these thresholds easily, generating fuller flavor perception.

Pods, limited by battery capacity and coil design, often fail to reach the full volatilization temperature range of complex flavorings. This can flatten top notes and under-deliver on flavor intensity.

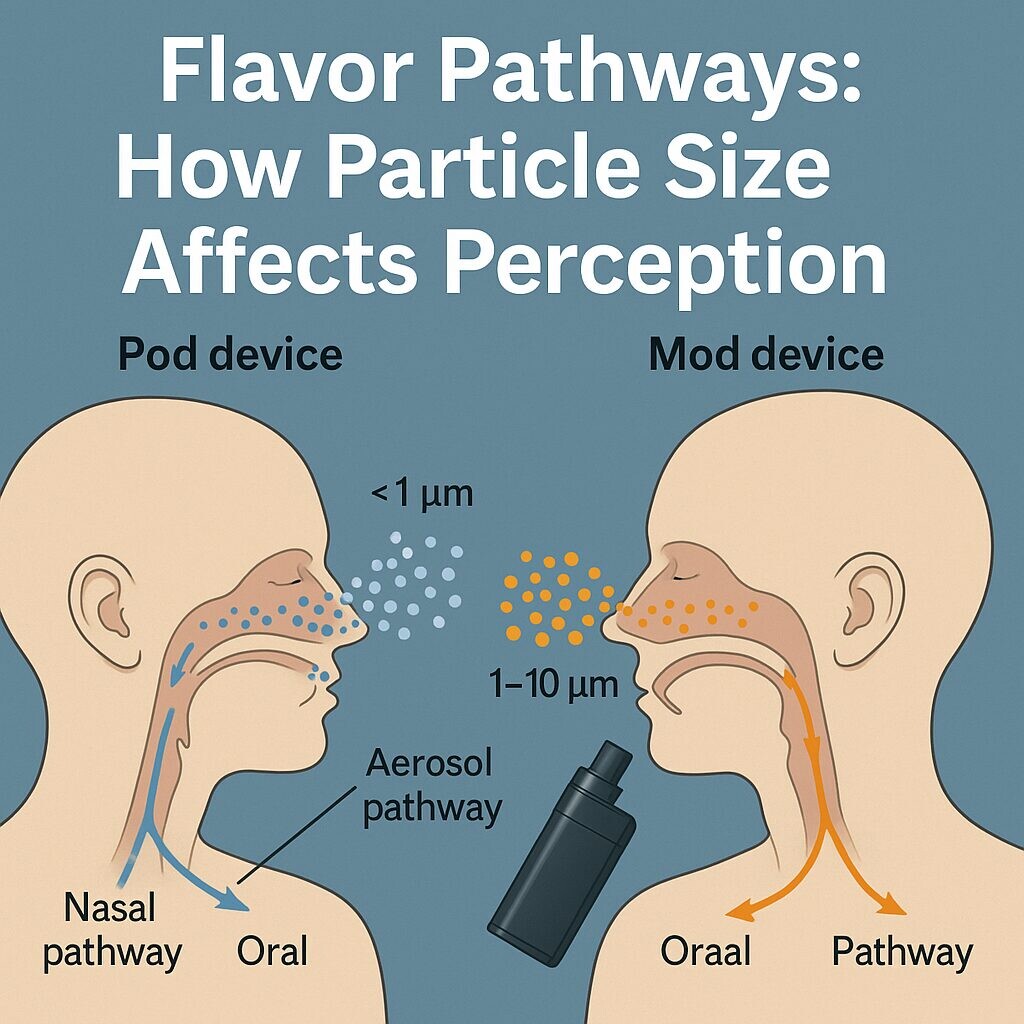

Particle size in aerosol affects how flavor is deposited in the mouth and nasal passages. Mod systems typically generate larger aerosol particles and more volume, enabling stronger retronasal olfaction (a key driver of flavor perception).

Higher nicotine levels, particularly in salt nicotine formats common in pod systems, significantly impact mouthfeel and flavor perception:

Formulators must adjust flavor intensity and type according to the nicotine format and device.

Volatile compounds are the carriers of flavor. In pod systems, slow heating and condensed air pathways reduce the release of these compounds. This leads to:

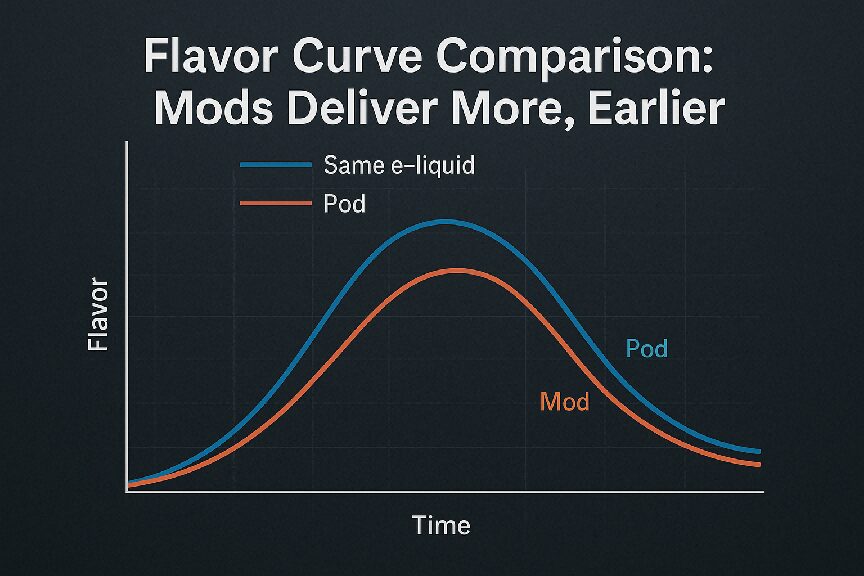

Mods offer broader evaporation spectrums due to rapid heating cycles, allowing for a more dynamic and expressive flavor experience.

The base composition plays a major role in how flavor behaves across devices:

Formulators must optimize viscosity, volatility, and emulsification for each device type.

Pod devices demand precision flavor engineering:

Mod systems are more forgiving but still benefit from specialized design:

The high temperatures in mods can degrade unstable flavor compounds. Common issues include:

In contrast, pod systems may preserve flavor longer but never unlock their full potential.

Case Description:

A commercial strawberry-flavored e-liquid performed poorly in a 1.2 ohm pod system. Vapers complained of an “artificial” or “flat” taste.

Root Cause:

Reformulated Version:

Result:

Flavor perception improved by 45% in blind testing on pods, while still delivering full notes in mod systems.

At CUIGUAI Flavoring, we formulate e-liquid flavorings designed for precise thermal and device behavior. Our pod-optimized flavors use advanced carriers and emulsification techniques to ensure consistent flavor delivery even under low-wattage conditions. Meanwhile, our mod-specific flavorings retain high-intensity notes and support thermal stability at elevated temperatures.

Whether you’re targeting MTL pod users or DL mod enthusiasts, CUIGUAI offers tailored solutions backed by formulation science.

In the competitive world of e-liquid development, understanding how hardware interacts with flavor can make or break your product. Pods and mods represent two very different vaporization environments. Formulators must adjust flavor architecture—not just intensity—to suit these platforms.

Don’t let your best flavors go unnoticed. Formulate with the device in mind.

Keyword:

pod vs mod flavor performance, vapor device flavor behavior

Article author: Toby Zhu

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy